Benefits of Steel Doctor Blades compare with Plastic made

Please contact Nick

to discuss your Doctor Blades

Office: +44 (0) 114 244 0527 Ext: 129

Email: nick.wright@fernite.co.uk

Mobile: 07480 254837

WhatsApp: 07480 254837

Mon – Thu: 8.30am-5.00pm

Fri: 8.30am – 3.45pm

Sat-Sun: Closed

If you prefer to send a contact form

please follow the link

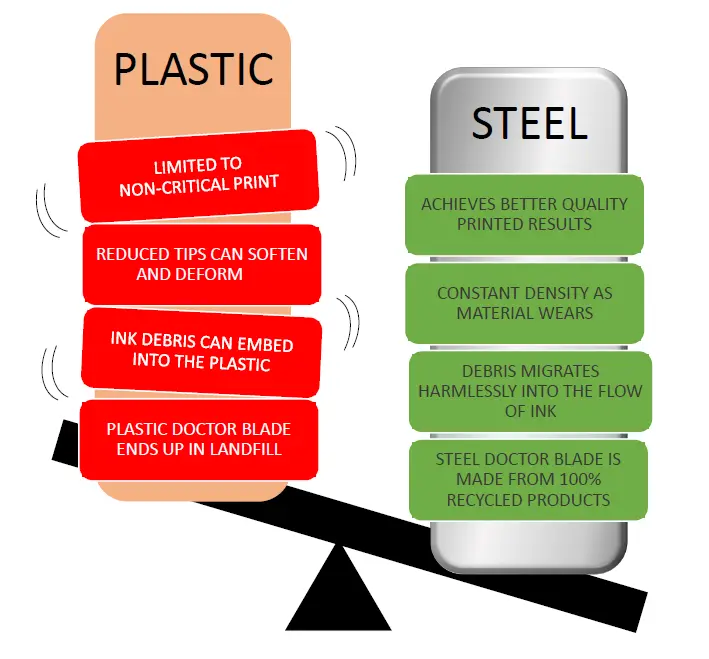

Benefits of a Steel Doctor Blade far outweigh those of a Plastic Doctor Blade.

Plastic Doctor Blades

- Whilst plastic has its place in the print industry, it is limited to non-critical print or coating applications.

- It can offer long life and perform well for industrial applications, but falls short for doctoring a precision film of ink when compared to steel.

- Plastic has a complex recycling process and many products (including doctor blades) end up in landfill.

- The plastic that is disposed of can take many years to break down in the environment or, when incinerated, emits carbon dioxide.

Steel Doctor Blades

- Steel is the first choice Doctor Blade for the majority of printers around the world

- The vast majority of manufactured strip steel is made from 100% recovered steel

- Specially developed steels have been made to meet the challenges of the flexo ink transfer process

- Steel can achieve and maintain a thinner contact area to ensure better print results

- As the material wears the structure of the blade remains the same

- As the blade wears it breaks into tiny particles which migrate easily into the flow of ink